Client: VOLKSWAGEN

Location: Portugal (Portugal)

Programación y puesta en marcha. Tecnología PLC y HMI SIEMENS.

Client: GESTAMP SOLAR (RENAULT)

Location: Fábrica de Newton (UK) (United Kingdom)

Programación y puesta en marcha de 2 lineas de soldadura, para fábrica de Gestamp en UK

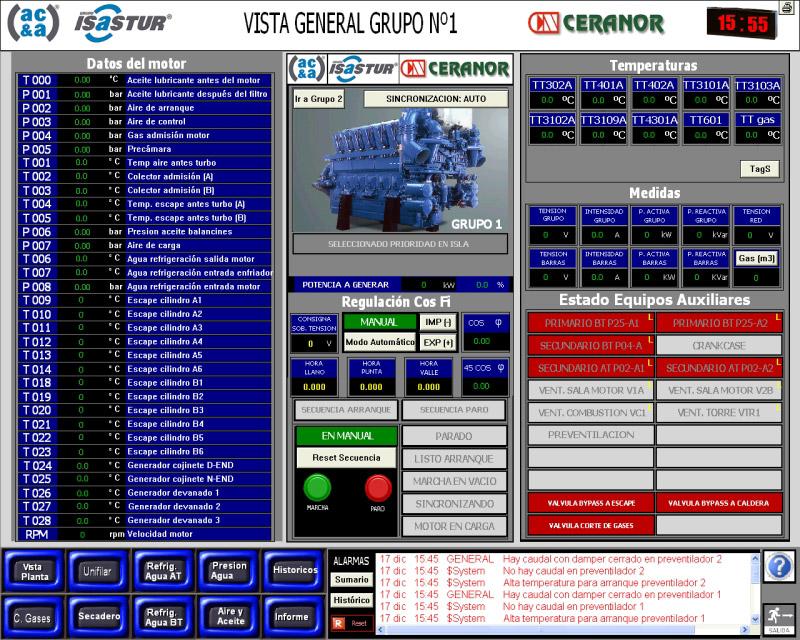

Client: CERANOR

Location: Spain

Control system of auxiliary services for Phase 1 and 2 of the CERANOR Don Juan cogeneration plants in Valencia, including connection with the PLC control systems of the groups to display all statuses/controls on screen. SIEMENS PLC-based system and SCADA INTOUCH system.

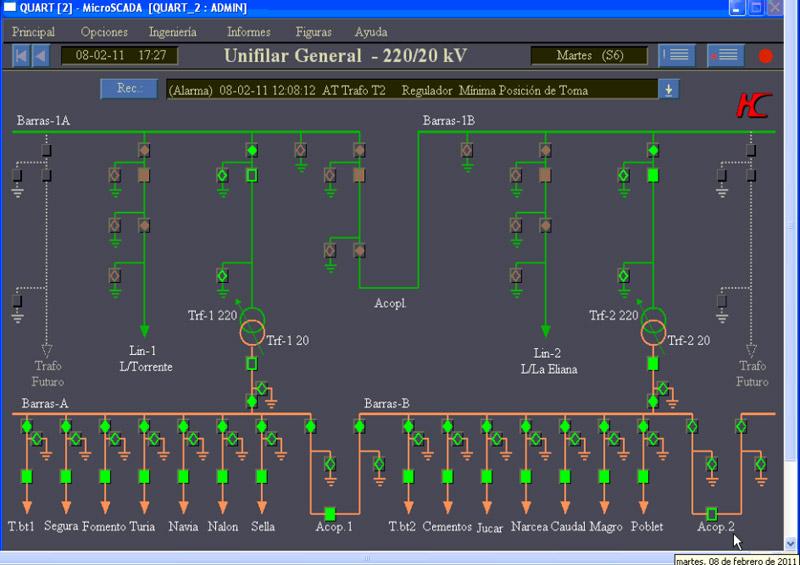

Client: HIDROELECTRICA DEL CANTABRICO

Location: Spain

Development of systems to perform monitoring and control of substations and transmission centres. The ABB scada system was used: MicroSCADA. Enables remote control with interlocks and connections with field units and control and protection units through various communication protocols. At the same time, microscada systems communicate with the office to ensure centralised control.

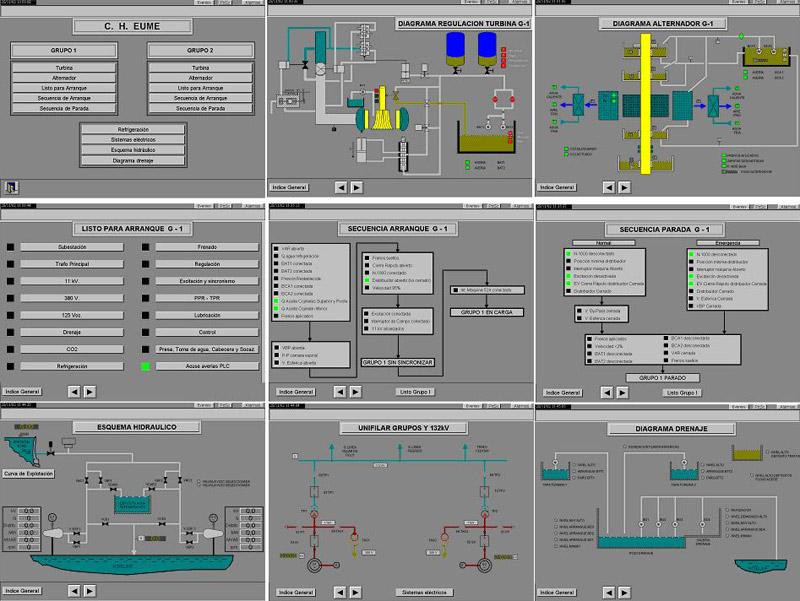

Client: ENDESA

Location: Spain

Updating throughout the years of the control systems of several hydropower plants and installing S7-400 programmable automation, SIEMENS SCADA WinCC and PROFIBUS networked remote control system. Plants covered by the works: EUME, PRADA, SAN SEBASTIAN, BARCENA, LAS ONDINAS, CORNATEL, QUEREÑO.

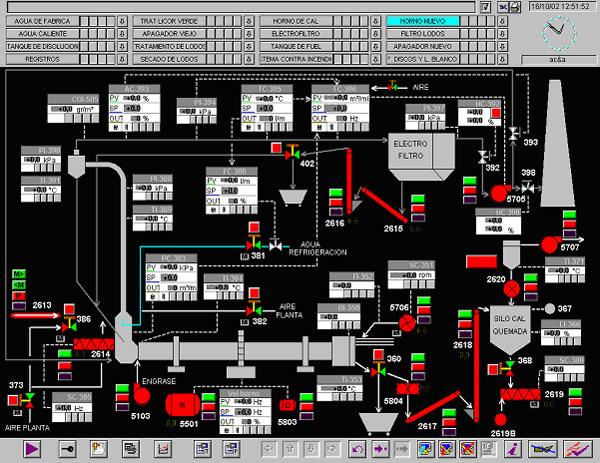

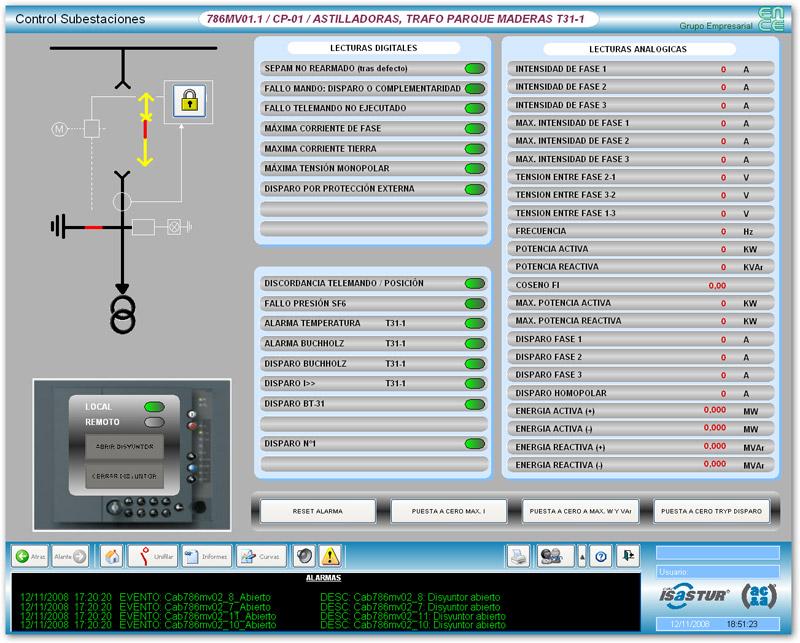

Client: GRUPO EMPRESARIAL ENCE

Location: Spain

Replacement of monitoring systems of various areas (lime kiln, washing-bleaching, resin-extracting plant and paper pulp machine) in the PLC-Scada designed process at the hybrid system. The various hybrid systems at the plant are connected to one another and to other systems responsible for other parts of the process through different protocols (profibus, Ethernet, modbus RTU, etc.)

Client: GRUPO EMPRESARIAL ENCE

Location: Spain

Programming supply and start-up of a system to monitor the factory's high/low voltage distribution centre. The system has a scada-plc design with direct connection to the protection equipment at the distribution panels.

Client: Solaire Direct

Location: Caborca, Sonora (Mexico)

Diseño y construcción de la planta solar fotovoltaica Abril de 130 MW en Sonora.

Client: NORDEX

Location: Argentina

Construcción del BOP eléctrico, la red de media tensión, la subestación de34/132 kV, y la línea de evacuación de 132 kV para el parque eólico de Pomona en Rio Negro, Argentina.

Client: OPDE

Location: Cádiz (Spain)

Diseño y construcción de la planta solar fotovoltaica Miramundo de 50 MW, incluyendo la construcción de la subestación transformadora 30/132 kV y la línea de interconexión.

Client: Solaire Direct

Location: Aguascalientes (Mexico)

Construcción de la planta solar fotovoltaica de Trompezón de 158 MW en Aguascalientes, México.

Client: ENEL GREEN POWER

Location: Mexico

Construcción del BOP civil, caminos, plataformas, red de media tensión y cimentaciones de las turbinas del parque eólico de Salitrillos en Reynosa, Tamaulipas.

Client: EDP RENOVAVEIS, S.A.

Location: Spain

Construction of the wind farm made up by 36 Gamesa 850 kW wind turbines 36 turbines G52 of 850 kW.

Client: OPDE

Location: Zaragoza (Spain)

Diseño, ingeniería, gestión y dirección de obra, suministro, montaje, construcción y puesta en servicio de la Planta Fotovoltaica Los Belos 49,96 MWp (La Muela, Zaragoza) y El Muelle 11,24MWp (Muel, Zaragoza), incluyendo las infraestructuras para la evacuación de la energía eléctrica a la subestación transformadora Dalton de 95MVA 30/220kV.

Client: ENEL GREEN POWER

Location: Chile (Chile)

Construcción del parque eólico de Taltal de 99 MW en Chile y de la subestación colectora 30/220 kV. El parque consta de 33 aerogeneradores VESTAS V90 de 3 MW.

Client: VESTAS EOLICA

Location: Argentina

Construcción del BOP eléctrico, la red de media tensión, la nueva subestación 33/132kV del parque eólico, la bahía de interconexión en subestación de Transba y la línea de evacuación de 132 kV.

Client: EDP RENOVAVEIS, S.A.

Location: Spain

Construction of the wind farm made up by 50 Gamesa 850 kW wind turbines 50 turbines G52 of 850 kW.

Client: ACCIONA CESA

Location: Spain

Construction of the wind farm made up by 11 Gamesa 2 MW wind turbines 11 turbines G90 of 2 MW.

Client: AES

Location: San Fernando (Colombia)

Construcción llave en mano de la planta solar fotovoltaica Nueva Castilla de 20,4 MWn propiedad de Ecopetrol.

Client: EDP RENOVAVEIS, S.A.

Location: Spain

Construction of the wind farm made up by 13 Ecotecnia 1.67 MW wind turbines.

Client: EDP RENOVAVEIS, S.A.

Location: Rumanía (Romania)

Construcción del parque eólico de Facaeni de 72 MW en Rumanía, incluyendo la subestación colectora 400/110/30 kV y la línea subterránea de 400 kV. El parque consta de 24 aerogeneradores VESTAS V100 de 3 MW.

Client: GUASCOR SOLAR ITALIA

Location: Italia (Italy)

Construcción de la planta solar fotovoltaica de Sabaudia de 6 MW en Italia

Client: UTE ABENER HASSI R'MEL CONSTRUCTION

Location: Algerie

Supply and assembly of the instrumentation and control facilities.

Client: NORDEX

Location: Artigas (Uruguay)

Isotron se hará cargo de los movimientos de tierras para caminos, plataformas, excavaciones de fundaciones, fundaciones de WTG, así como del diseño, suministro y construcción “llave en mano” de la subestación transformadora de 150 kV. También ejecutará la conexión “T” a la línea de transmisión de 150kV (entre las sub-estaciones Tomas Gomensoro y Artigas), así como la comunicación y teleprotección en ambas estaciones y el sistema colector de los aerogeneradores del Parque Eólico integrado por 28 turbinas N117 NCV 2.4 MW 50 Hz IEC3(a) para un total de 67,2 MW de potencia instalada.

Client: IBERDROLA

Location: México ()

Montaje electromecánico completo de 80 MW de la planta solar Santiago de 220 MW localizada en Villa de Pozo en el Estado de San Luis de Potosí en México.

Client: CANADIAN SOLAR

Location: Aguascalientes (Mexico)

Diseño y construcción de la planta solar Horus de 95 MWn en México.

Client: Solaire Direct

Location: Comondú, Baja California Sur (Mexico)

Diseño y construcción de la planta solar fotovoltaica Sol de Insurgentes de 31 MW en Baja California, incluyendo la instalación de un sistema de baterías y la subestación y la línea para la interconexión a la red en 115 kV.

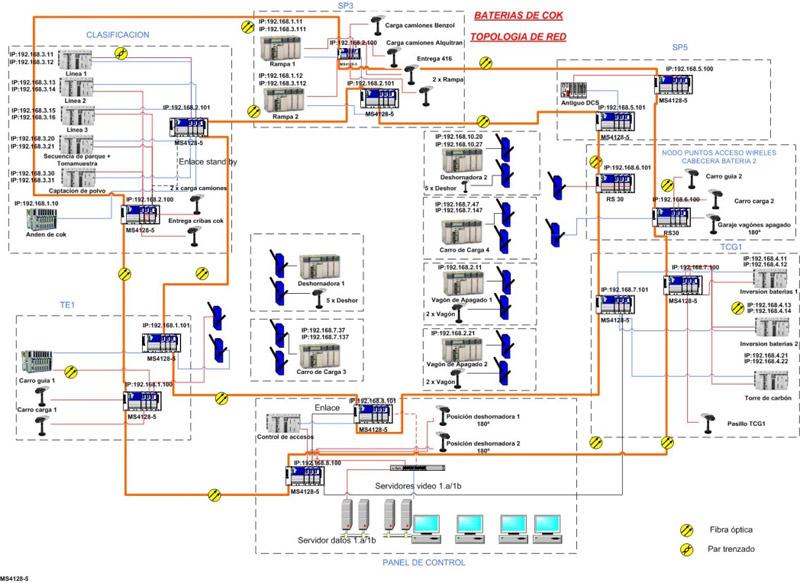

Client: ARCELORMITTAL ESPAÑA, S.A.

Location: Spain

Programming supply and start-up of a system to monitor and control the coke batteries at the steelworks. The system includes:

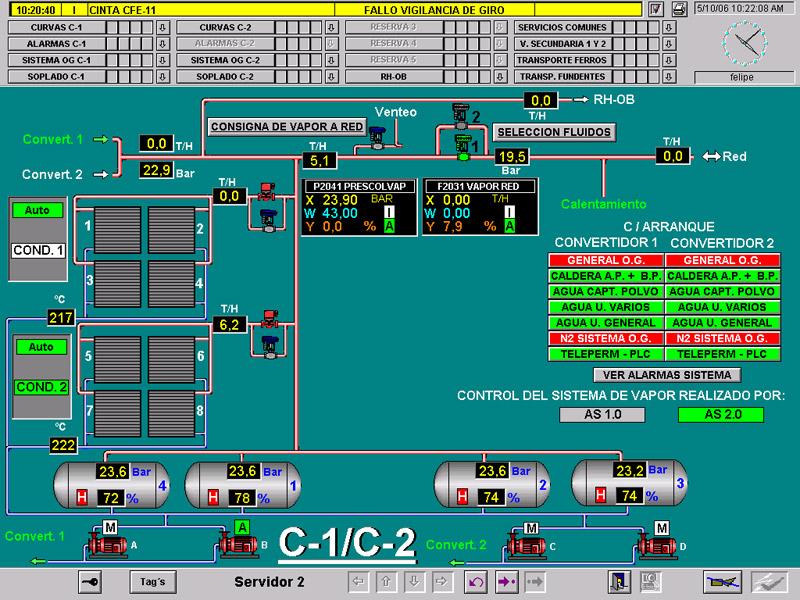

Client: ARCELORMITTAL ESPAÑA, S.A.

Location: Spain

Control system made up for S7-400 programmable automation, SIEMENS SCADA WinCC monitoring and SIEMENS TELEPERM distributed control. Point-to-point TTY communication via RK51 protocol. Project performed in line with scheduled, one-off shut-downs during facility hours. All the common parts of the 2 existing converters (steam system) were duplicated to enable alternative operation. The existing programming was adapted both in the PLCs and in the DCS to ensure that operation responded to the functional description provided by the technicians.

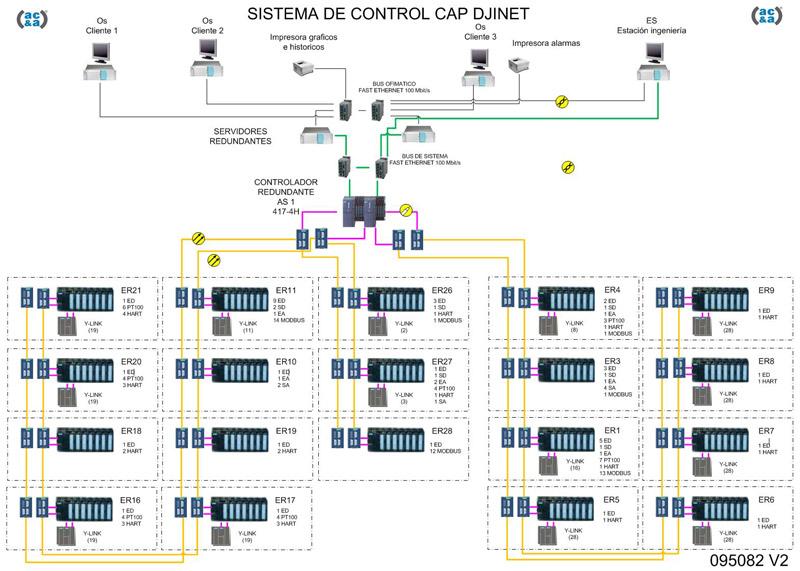

Client: ISOTRON

Location: Algerie

Programming supply and start-up of a system to monitor and control the desalination plant. The control architecture has:

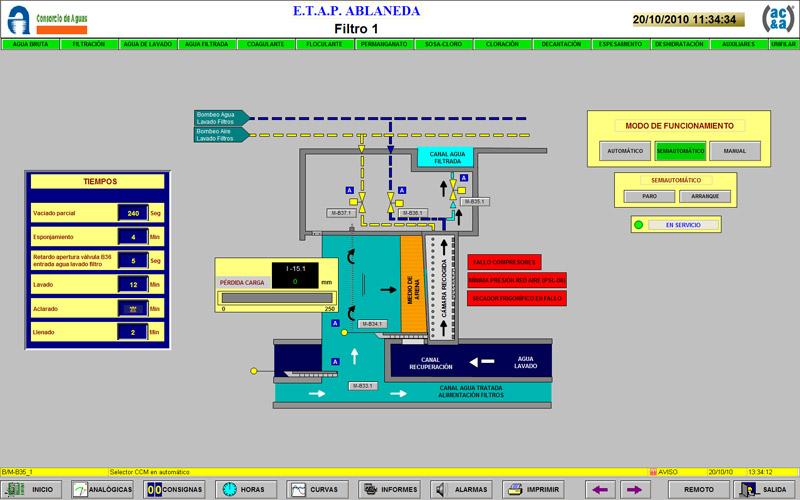

Client: UTE AQUALIA/FCC

Location: Spain

The Ablaneda drinking water treatment plant is located in the municipality of Corvera de Asturias and works to treat water from the Narcea river to ensure supply to the coastal towns. The control system has PLCs and Siemens SCADA WinCC and covers the following areas of the facilities: